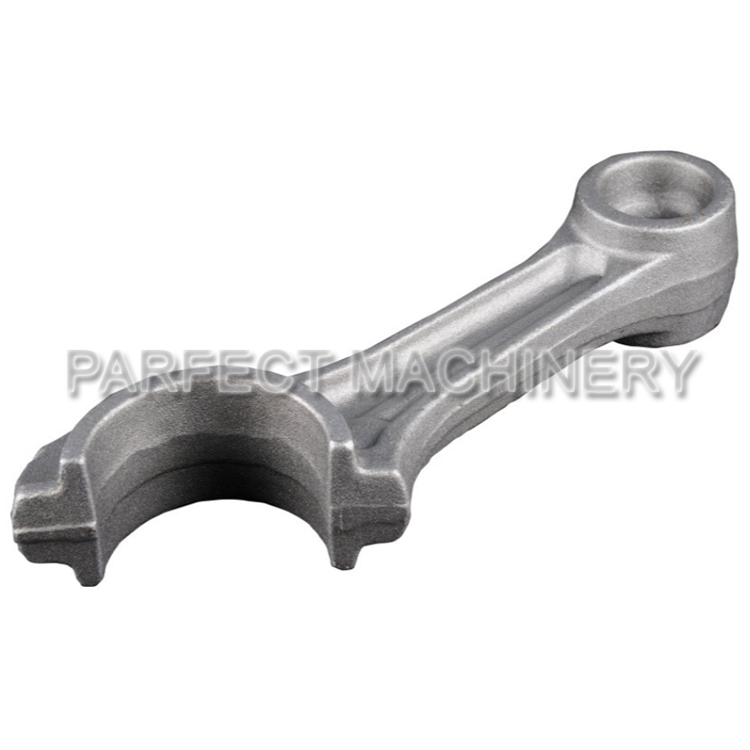

Steel connecting rod blanks are typically produced through forging, primarily in two forms: one is where the rod body and cap are forged as separate pieces, and the other is where they are forged as a single unit, which is later split open in the machining process, often using a fracture-splitting technique. The primary function of the finished connecting rod is to link the piston to the crankshaft, converting the piston's linear motion into rotational motion within an internal combustion engine.