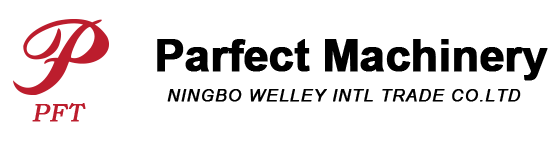

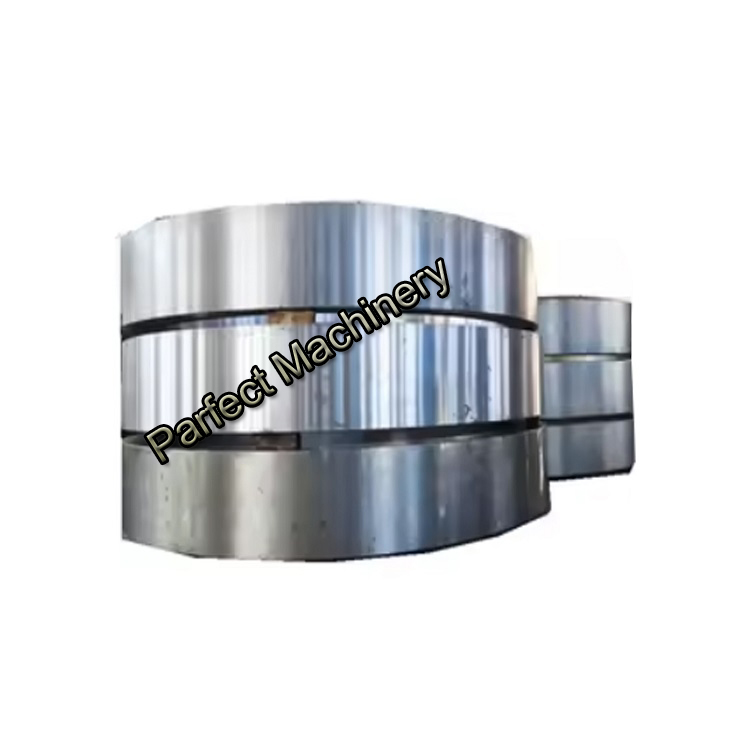

Alloy steel forging is a manufacturing process that uses heat and pressure to shape metal alloys, resulting in components with superior strength, toughness, and hardness. This is achieved by heating alloy steel billets to high temperatures before shaping them with presses or hammers, and often includes a heat treatment process like quenching and tempering to further enhance the material's properties. Common alloying elements include chromium, molybdenum, nickel, and manganese, which improve specific characteristics like wear resistance, strength at high temperatures, and corrosion resistance.