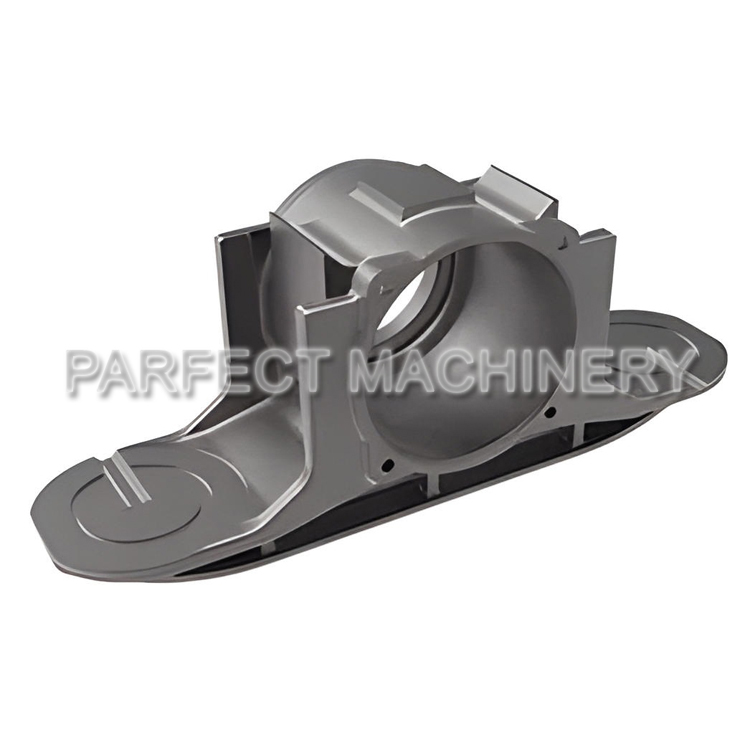

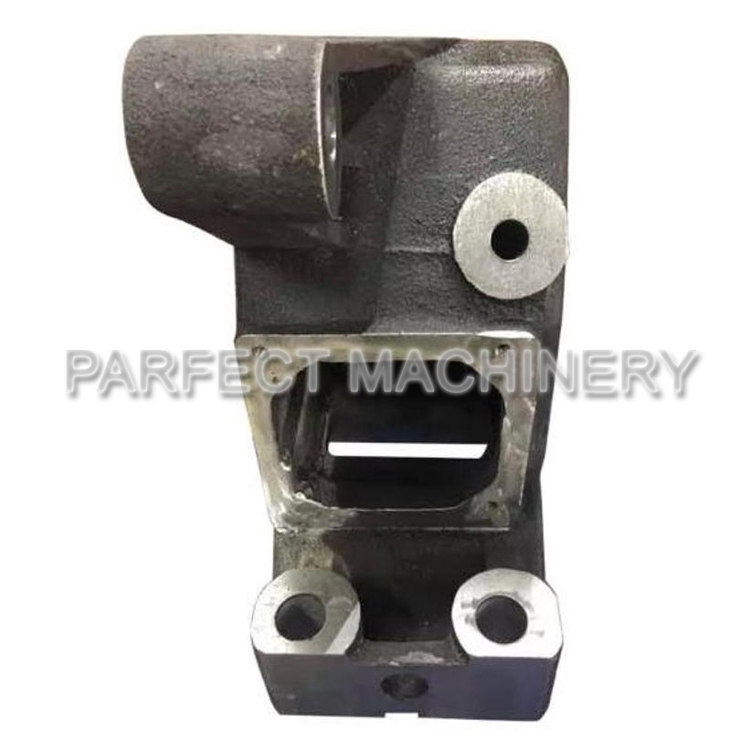

The steel casting Vehicle Axle Box is a pivotal load-bearing component in railway or heavy-duty vehicle suspension systems, housing bearings that support wheelset rotation while transmitting dynamic loads between the axle and bogie frame. Forged from high-strength alloy steel, it offers superior impact resistance, fatigue durability, and dimensional stability under constant vibration, heavy cargo loads, and extreme operational stresses.

Its robust design features precision-machined bearing seats, integrated lubrication channels, and reinforced housing to minimize deformation and ensure smooth wheel movement. Advanced heat treatment and surface protection enhance wear resistance and corrosion defense, extending service life in harsh environments.

| Accurate in reading drawings & Fast in delivery & Exact dimension control & 100% quality control & OEM Service & Strict material inspection & Prompt quote & lead time guarantee | |

| 1. Product Name: | Vehicle Axle Box |

| 2. Material: | Carbon Steel, Alloy Steel, Stainless Steel, Manganese steel, etc |

| 3. Material Standard: | ASTM,AISI,ASME,SAE,NF EN,DIN EN,ISO,,BS EN,SS,etc. |

| 4. Items: | FOB Ningbo or Shanghai,China |

| 5. Lead time: | 30~40 days |

| 6. Place of origin | Ningbo, China |

| 7. Software for specification drawings: | PDF, Auto CAD, Solidworks, JPG, ProE,etc. |

| 8. Main production equipments: | Wax injection, CNC-machine-center, Lathe, Milling machine,Drilling machine,Boring Lathe,Grinding Machine, Heat treatment Furnace. |

| 9. Heat Treatment Machine: | Mesh-Belt-Furnace,Carburizing Quench Furnace,Chamer Furnace,etc. |

| 10. Surface Treatment: | Cold/Hot Zn Plating,Blackening Treatment(Salt Spray Test 48-96 hours),Ni Plating,Cr Plating,Spraying Undercoat,Anti-Rust Paint,Surface Paint,Plastic Paint,Coated Anti-Rust Water,Anti-oil,etc. |

| 11. Surface Heat Treatment: | Medium Frequence Quenching,High Frequence Quenching and Carburizing and Quenching,Oil Quenching,Water quenching,Normalizing,Temper,Annealing,etc. |

| 12. Dimension Inspection: | Calipers,Height Laugue,Micrometer Calipers,Inside Caliper Gauge,Angle and R Gauge,Three coordinates measuring instrument. |

| 13. Productivity: | 50000 pcs / year |

| 14. Packaging: | Wooden package after mandatory treatment or other |

| 15. They are using for mining equipment, Construction equipment, Agricultural equipment and others. | |

| 16. We make Vehicle Axle Box,investment casting ,Lost wax casting,Lost foam casting,Silica sol casting and steel sand casting in Ningbo, China | |

| 17. Export Markets: ⑴ Australia Vehicle Axle Box parts; ⑵ America, U.S.A. United States Vehicle Axle Box parts; ⑶Canada Vehicle Axle Box parts; ⑷ U.K. England, Britain Vehicle Axle Box parts; ⑸ Germany Vehicle Axle Box parts; ⑹ France Vehicle Axle Box parts; ⑺ Italy Vehicle Axle Box parts; ⑻ Spain Espana Vehicle Axle Box parts; ⑼ Holand Vehicle Axle Box parts; ⑽ South Africa Vehicle Axle Box parts; ⑾ Danmark Vehicle Axle Box parts; ⑿ Sweden Vehicle Axle Box parts; ⒀ Finland Vehicle Axle Box parts | |

| 18. Supplier:China Vehicle Axle Box factory;China Precision company;China Co.,Ltd;China Vehicle Axle Box INC;China Vehicle Axle Box corporation;China Vehicle Axle Box Manufacturer;China Vehicle Axle Box supplier; China Vehicle Axle Box parts, China Vehicle Axle Box foundry. | |

| 19. Relationship Information:Ningbo Vehicle Axle Box factory;Ningbo Precision company;Ningbo Vehicle Axle Box Co.,Ltd;Hangzhou Vehicle Axle Box factory;Hangzhou Vehicle Axle Box company;Hangzhou Vehicle Axle Box Co.,Ltd;Zhejiang Vehicle Axle Box company;Zhejiang Vehicle Axle Box Co.,Ltd. | |

| If you have any other question, please feel free to contact us. | |