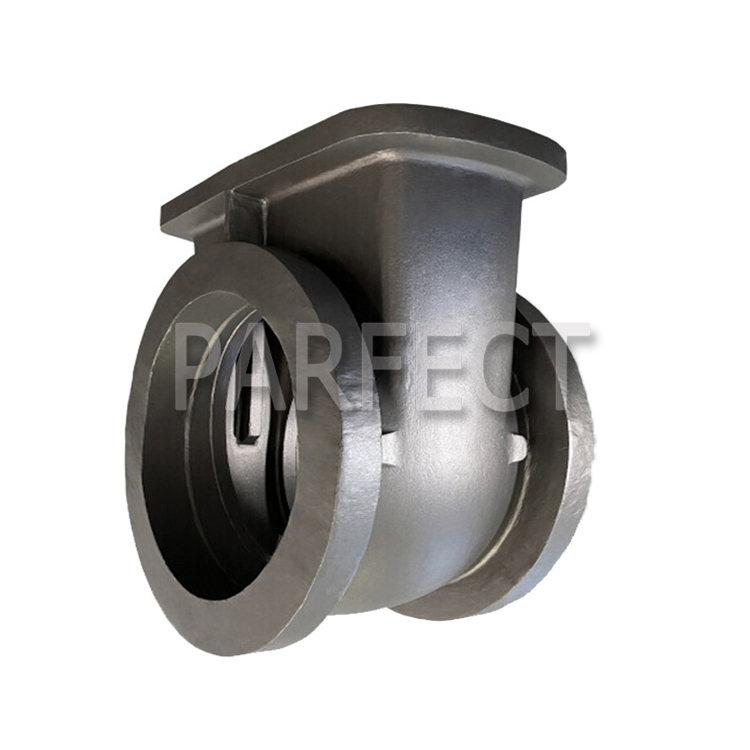

As a leading manufacturer specializing in custom castings and forgings, we deliver high-performance gate valves engineered to meet the unique demands of oil & gas, municipal water, power generation, and HVAC sectors. Our gate valves stand out for their robust construction—combining precision-cast bodies and durable forged components—to ensure tight shut-off, long service life, and seamless adaptability to diverse working conditions.

We don’t just supply gate valves; we craft solutions tailored to your exact specifications. Our cast and forged gate valves blend flexibility, quality, and cost-effectiveness.we tailor every detail to your drawings & working conditions.

You Can Get Free Technical Consultation & Competitive Quotation Within 24 Hours.

| Detailed Feature: | |

| Accurate in reading drawings & Fast in delivery & Exact dimension control & 100% quality control & OEM Service & Strict material inspection & Prompt quote & lead time guarantee | |

| 1.Product Name: | Gate Valve |

| 2. Material: | Gray Iron, Ductile Iron,Carbon Steel,Alloy Steel |

| 3.Material Standard: | ASTM,AISI,ASME,SAE,NF EN,DIN EN,ISO,BS EN,SS,etc. |

| 4. Items: | FOB Ningbo or Shanghai,China |

| 5. Lead time: | 30~40 days |

| 6. Place of origin | Ningbo, China |

| 7. Software for specification drawings: | PDF, Auto CAD, Solidworks, JPG, ProE,etc. |

| 8. Main production equipments: | Mold build, CNC-machine-center, Lathe, Milling machine,Drilling machine,Boring Lathe,Grinding Machine, Heat treatment Furnace. |

| 9.Heat Treatment Machine: | Mesh-Belt-Furnace,Carburizing Quench Furnace,Chamer Furnace,etc. |

| 10.Surface Treatment: | Cold/Hot Zn Plating,Blackening Treatment(Salt Spray Test 48-96 hours),Ni Plating,Cr Plating,Spraying Undercoat,Anti-Rust Paint,Surface Paint,Plastic Paint,Coated Anti-Rust Water,Anti-oil,etc. |

| 11.Surface Heat Treatment: | Medium Frequence Quenching,High Frequence Quenching and Carburizing and Quenching,Oil Quenching,Water quenching,Normalizing,Temper,Annealing,etc. |

| 12.Dimension Inspection: | Calipers,Height Laugue,Micrometer Calipers,Inside Caliper Gauge,Angle and R Gauge,Three coordinates measuring instrument. |

| 13. Productivity: | 50000 pcs / year |

| 14. Packaging: | Wooden package after mandatory treatment or other |

| 15. They are using for mining equipment,Construction equipment,Agricultural equipment and others. | |

| 16. We make valve casting,machining,investment casting ,Lost wax casting,Lost foam casting,Silica sol casting and steel sand casting in Ningbo, China | |

| 17. Export Markets: ① Australia Valve Casting parts; ② America, U.S.A. United States Valve Casting parts; ③Canada Valve Casting parts; ④ U.K. England, Britain Valve Casting parts; ⑤ Germany Valve Casting parts; ⑥ France Valve Casting parts; ⑦ Italy Valve Casting parts ⑧ Spain Espana Valve Casting parts; ⑨ Holand Valve Casting parts ⑩ South Africa Valve Casting parts; ⑾ Danmark Valve Casting parts ⑿ Sweden Valve Casting parts; ⒀ Finland Valve Casting parts | |

| 18.Supplier:China Valve Casting factory;China Precision company;China Co.,Ltd;China Valve Casting INC;China Valve Casting corporation;China Valve Casting Manufacturer;China Valve Casting supplier; China Valve Casting parts, China Valve Casting foundry. | |

| 19.Relationship Information:Ningbo Valve Casting factory;Ningbo Precision company;Ningbo Valve Casting Co.,Ltd;Hangzhou Valve Casting factory;Hangzhou Valve Casting company;Hangzhou Valve Casting Co.,Ltd;Zhejiang Valve Casting company;Zhejiang Valve Casting Co.,Ltd. | |

| If you have any other question, please feel free to contact us. | |