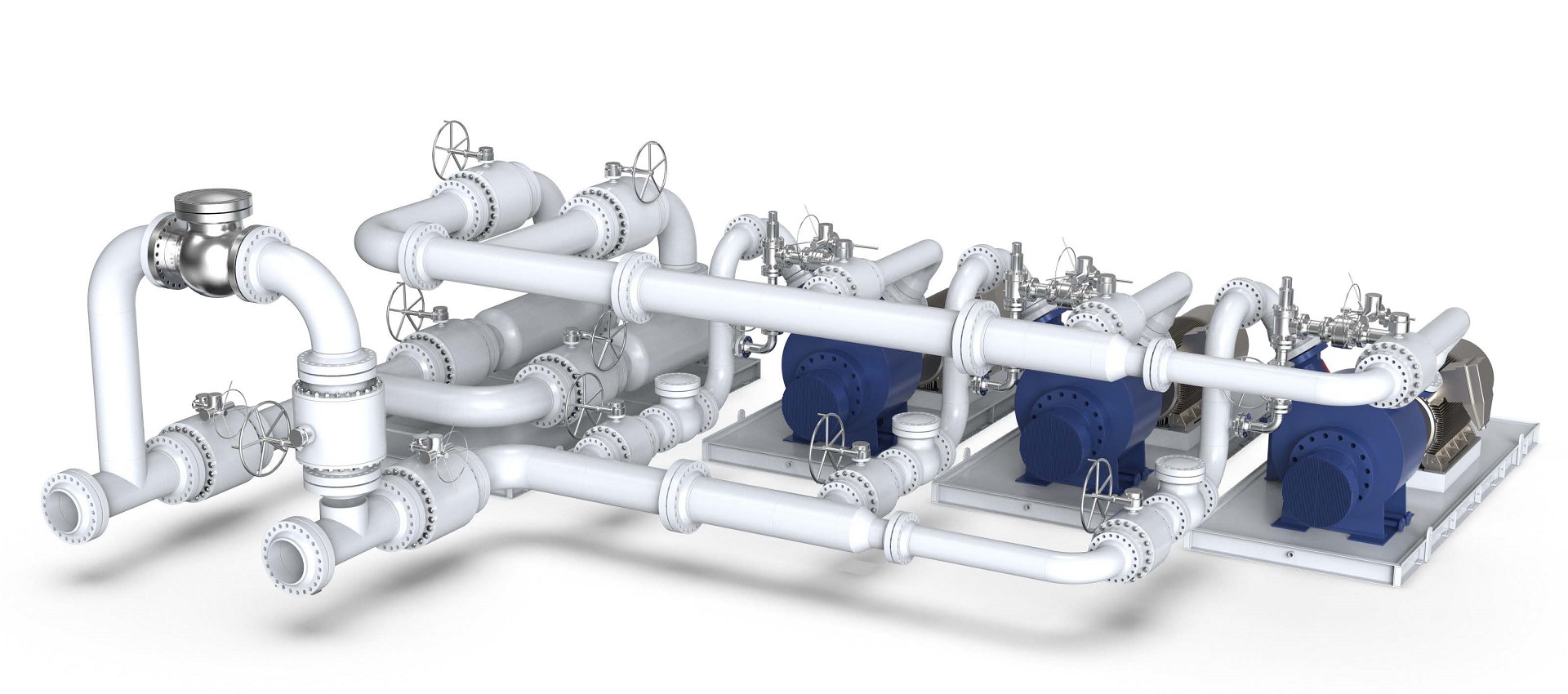

Centrifugal pump castings are specialized components meticulously manufactured through casting techniques to form the essential structural parts of centrifugal pumps, which operate by converting rotational kinetic energy into hydraulic energy to move fluids. These castings, commonly crafted from robust materials like stainless steel, cast iron, or high-grade alloys, are designed to endure the dynamic forces, high velocities, and potential cavitation effects inherent in centrifugal pump operation. Key castings include the pump casing, which encloses and guides the fluid flow; the impeller, responsible for imparting energy to the fluid; and the volute or diffuser, which helps convert velocity energy into pressure energy. The precision and quality of these castings are paramount in ensuring the efficiency, reliability, and longevity of centrifugal pumps across a wide range of industrial, commercial, and residential applications.