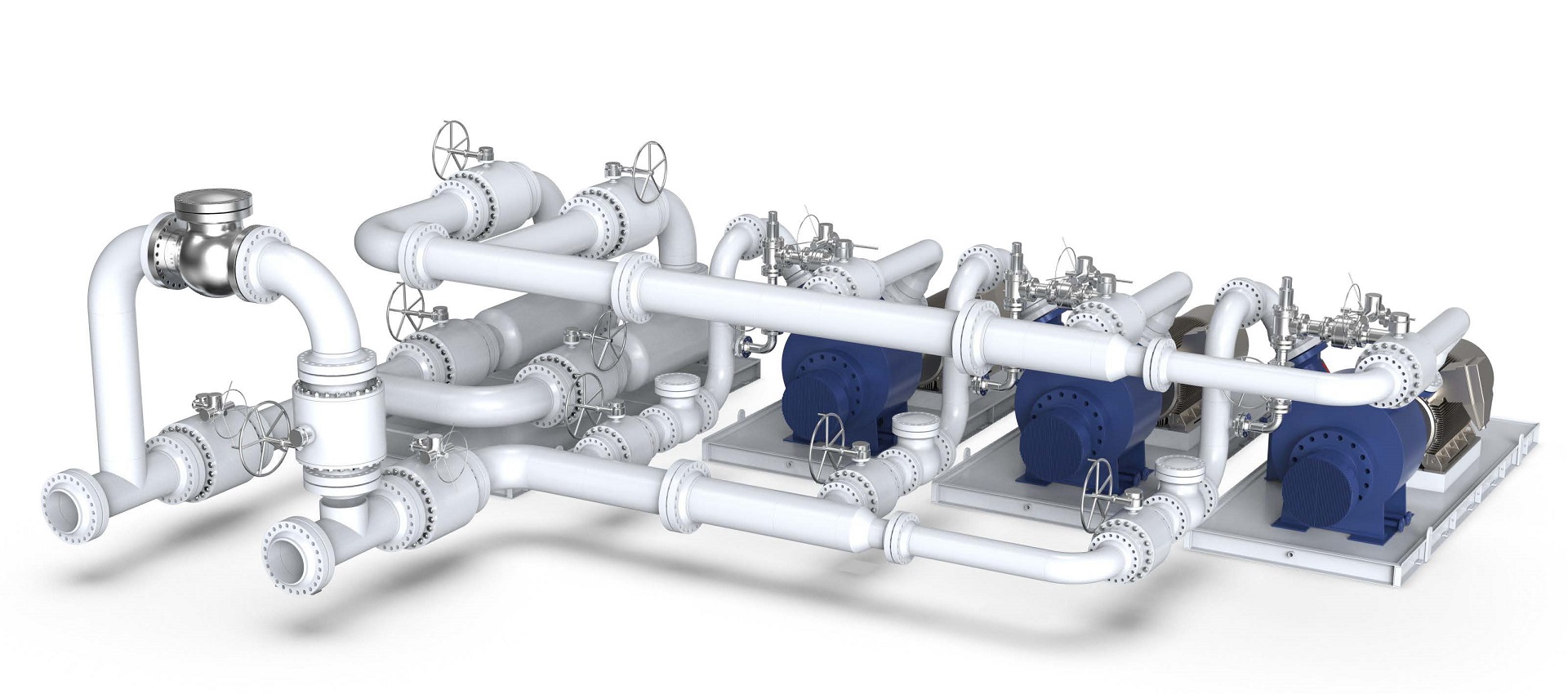

Valve lost wax castings, also known as investment castings, are renowned for their exceptional dimensional accuracy and superior surface finish. This intricate process begins with creating a precise wax pattern of the valve component, which is then assembled into a cluster and repeatedly dipped in ceramic slurry to form a solid mold. Once fired, the wax melts away, leaving a perfect cavity into which molten metal - such as stainless steel, carbon steel, or special alloys - is poured. This method ensures exceptional dimensional consistency, smooth surface finishes, and intricate internal geometries, making it ideal for producing critical valve components like bodies, bonnets, and trim, which demand tight tolerances and reliable performance in demanding industries such as oil and gas, chemical processing, and power generation.