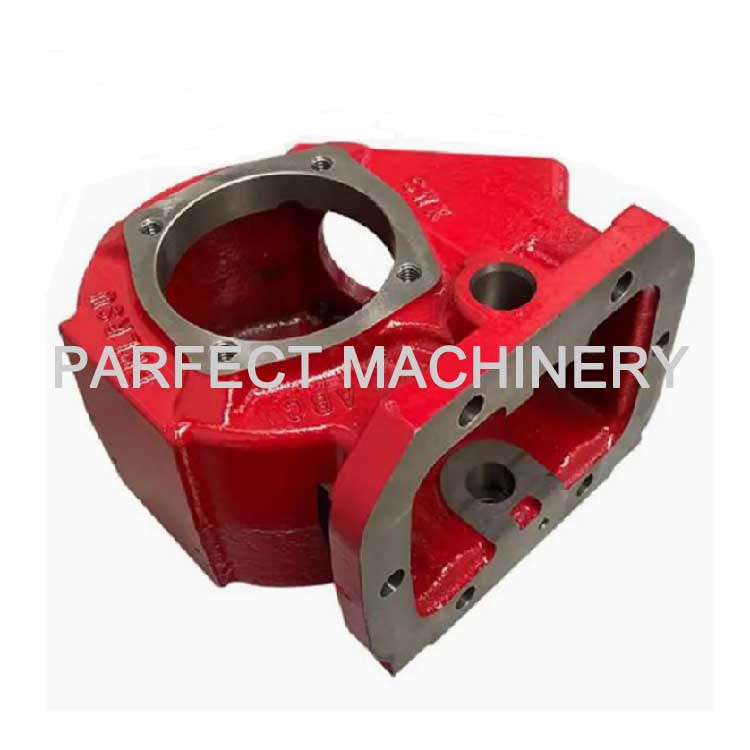

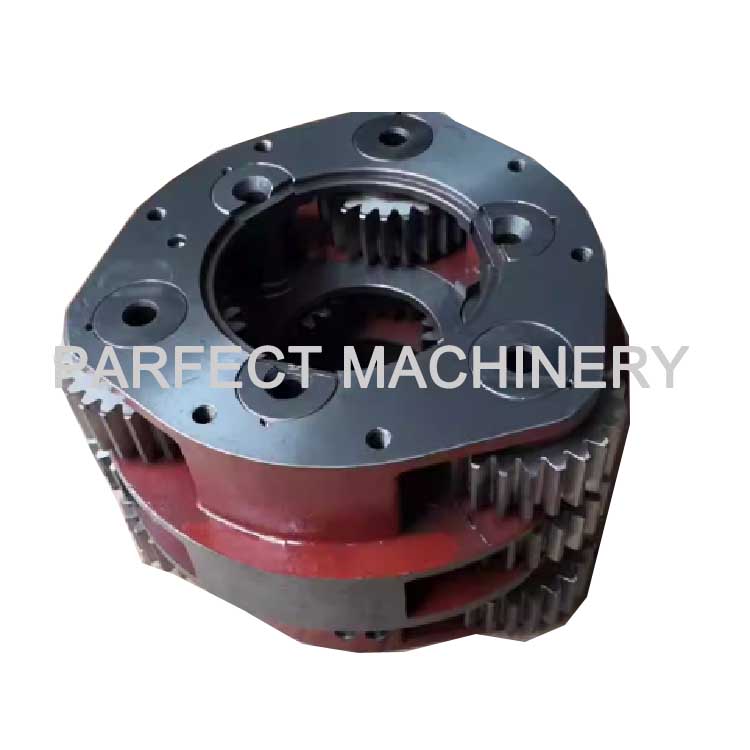

Bulldozer castings are vital components produced via the casting process, specifically engineered to endure the harsh and heavy-duty operating conditions of bulldozers. These castings, which include critical parts such as the blade, frame, tracks, and various support structures, are typically made from high-strength, wear-resistant materials like alloy steel or hardened cast iron. The casting technique allows for the creation of complex geometries and robust designs that can withstand immense forces, impacts, and abrasive environments encountered during earthmoving and grading tasks. Their durability and resilience ensure that bulldozer castings maintain structural integrity, minimize downtime, and contribute to the overall efficiency and longevity of the bulldozer in demanding construction and mining applications.

| Accurate in reading drawings & Fast in delivery & Exact dimension control & 100% quality control & OEM Service & Strict material inspection & Prompt quote & lead time guarantee | |

| 1.Product Name: | bulldozer castings |

| 2.Material: | Cast Iron, Cast Steel, Stainless Steel, Alloy Steel, Aluminium Alloy |

| 3.Material Standard: | ASTM,AISI,ASME,SAE,NF EN,DIN EN,ISO,,BS EN,SS,etc. |

| 4.Items: | FOB Ningbo or Shanghai,China |

| 5.Lead time: | 30~40 days |

| 6.Place of origin | Ningbo, China |

| 7.Software for specification drawings: | PDF, Auto CAD, Solidworks, JPG, ProE,etc. |

| 8.Main production equipments: | Wax injection, CNC-machine-center, Lathe, Milling machine,Drilling machine,Boring Lathe,Grinding Machine, Heat treatment Furnace. |

| 9.Heat Treatment Machine: | Mesh-Belt-Furnace,Carburizing Quench Furnace,Chamer Furnace,etc. |

| 10.Surface Treatment: | Cold/Hot Zn Plating,Blackening Treatment(Salt Spray Test 48-96 hours),Ni Plating,Cr Plating,Spraying Undercoat,Anti-Rust Paint,Surface Paint,Plastic Paint,Coated Anti-Rust Water,Anti-oil,etc. |

| 11.Surface Heat Treatment: | Medium Frequence Quenching,High Frequence Quenching and Carburizing and Quenching,Oil Quenching,Water quenching,Normalizing,Temper,Annealing,etc. |

| 12.Dimension Inspection: | Calipers,Height Laugue,Micrometer Calipers,Inside Caliper Gauge,Angle and R Gauge,Three coordinates measuring instrument. |

| 13.Productivity: | 50000 pcs / year |

| 14.Packaging: | Wooden package after mandatory treatment or other |

| 15.They are using for Construction Machinery Industry | |

| 16.We make investment casting, sand casting, forging, machining, stamping and welding in Ningbo, China | |

| 17. Export Markets: ① Australia bulldozer castings; ② America, U.S.A. United States bulldozer castings; ③Canada bulldozer castings; ④ U.K. England, Britain bulldozer castings; ⑤ Germany bulldozer castings; ⑥ France bulldozer castings; ⑦ Italy bulldozer castings ⑧ Spain Espana bulldozer castings; ⑨ Holand bulldozer castings; ⑩ South Africa bulldozer castings; ⑾ Danmark bulldozer castings; ⑿ Sweden bulldozer castings; ⒀ Finland bulldozer castings | |

| 18.Supplier: China bulldozer castings factory; China bulldozer castings company; China bulldozer castings Co.,Ltd; China bulldozer castings INC; China bulldozer castings corporation; China bulldozer castings manufacturer; China bulldozer castings supplier; | |

| 19.Relationship Information: Ningbo bulldozer castings factory; Ningbo Precision company; Ningbo bulldozer castings Co.,Ltd; Hangzhou bulldozer castings factory; Hangzhou bulldozer castings company; Hangzhou bulldozer castings Co.,Ltd; Zhejiang bulldozer castings company; Zhejiang bulldozer castings Co.,Ltd. | |

| If you have any other question, please feel free to contact us. | |