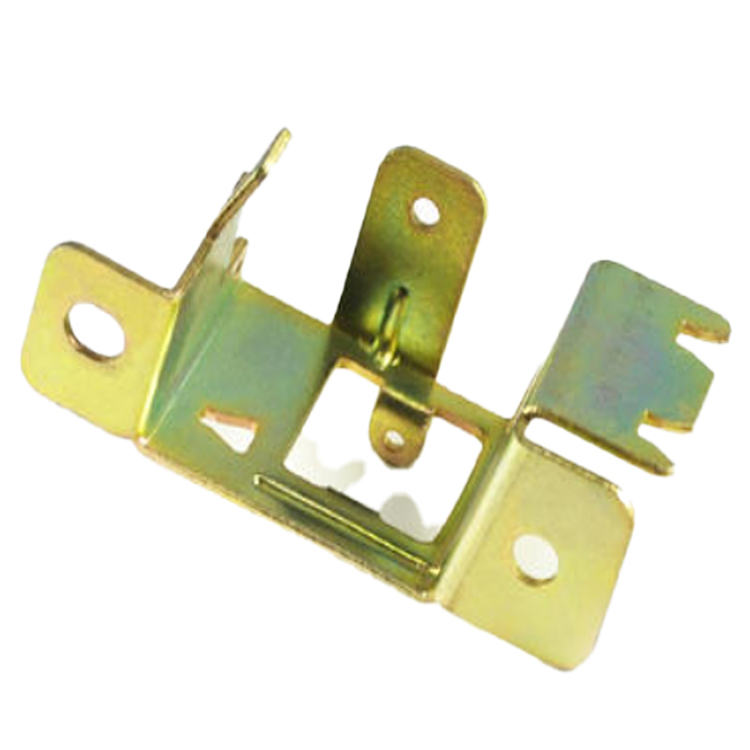

We are a China brass stamping parts company,Producing all kinds of brass stamping parts parts,We produce brass stamping parts process by stamping.We are the leader of China brass stamping parts company.The brass stamping parts in Chinese ompany is with good quality.Common materials for brass stamping parts parts are carbon steel,aluminum,brass,copper,stainless steel.We can produce brass stamping parts parts according to your requirements.Our brass stamping parts company have different sizes, brass stamping parts company has emerged as one of the top innovators. Our brass stamping parts parts exported to America,Canada,England,France,Germany,Australia & South Africa Holland,Spain market...!

| Detailed Feature: | |

| Accurate in reading drawings & Fast in delivery & Exact dimension control & 100% quality control & OEM Service & Strict material inspection & Prompt quote & lead time guarantee | |

| 1.Product Name: | brass stamping parts |

| 2. Material: | low-carbon steel , stainless steel , aluminum,zinc and copper. |

| 3.Material Standard: | ASTM,AISI,ASME,SAE,NF EN,DIN EN,ISO,BS EN,SS,etc. |

| 4. Items: | FOB Ningbo or Shanghai,China |

| 5. Lead time: | 30~40 days |

| 6. Place of origin | Ningbo, China |

| 7. Software for specification drawings: | PDF, Auto CAD, Solidworks, JPG, ProE,etc. |

| 8. Stamping process: | blanking (cutting flat pieces from sheets), piercing (creating holes), bending (forming angles or curves), drawing (shaping into 3D forms like cups or housings), and embossing (adding raised designs). |

| 9.Heat Treatment Machine: | Mesh-Belt-Furnace,Carburizing Quench Furnace,Chamer Furnace,etc. |

| 10.Surface Treatment: | Anodizing/black Anodizing/electrophoresissandblasting/ chemical treatment/Spray paint/ Hard anodizingHeat treatment /Galvanizing/ nickel plating/gold plating ,ect. |

| 11.Surface Heat Treatment: | Medium Frequence Quenching,High Frequence Quenching and Carburizing and Quenching,Oil Quenching,Water quenching,Normalizing,Temper,Annealing,etc. |

| 12.Dimension Inspection: | Calipers,Height Laugue,Micrometer Calipers,Inside Caliper Gauge,Angle and R Gauge,Three coordinates measuring instrument. |

| 13. Productivity: | 50000 pcs / year |

| 14. Packaging: | Wooden package after mandatory treatment or other |

| 15. They are using for automoblie,mining equipment,commercial food service,Military,Rail,Construction equipment,Agricultural equipment and others. | |

| 16. We make brass stamping parts,stamping,machining, in Ningbo, China | |

| 17. Export Markets: ① Australia brass stamping parts parts; ② America, U.S.A. United States brass stamping parts parts; ③Canada brass stamping parts parts; ④ U.K. England, Britain brass stamping parts parts; ⑤ Germany brass stamping parts parts; ⑥ France brass stamping parts parts; ⑦ Italy brass stamping parts parts ⑧ Spain Espana brass stamping parts parts; ⑨ Holand brass stamping parts parts ⑩ South Africa brass stamping parts parts; ⑾ Danmark brass stamping parts parts ⑿ Sweden brass stamping parts parts; ⒀ Finland brass stamping parts parts | |

| 18.Supplier:China brass stamping parts factory;China Precision company;China Co.,Ltd;China brass stamping parts INC;China brass stamping parts corporation;China brass stamping parts Manufacturer;China brass stamping parts supplier; China brass stamping parts parts, China brass stamping parts foundry. | |

| 19.Relationship Information:Ningbo brass stamping parts factory;Ningbo Precision company;Ningbo brass stamping parts Co.,Ltd;Hangzhou brass stamping parts factory;Hangzhou brass stamping parts company;Hangzhou brass stamping parts Co.,Ltd;Zhejiang brass stamping parts company;Zhejiang brass stamping parts Co.,Ltd. | |

| If you have any other question, please feel free to contact us. | |